Sustainable mobility is one of the automotive megatrends of 2023, if not of the current decade. Environmental protection has never been in the public and political spotlight as much as it is now: During the last World Environment Day, the UN announced its plans for stricter CO2 reduction regulations; many countries, including China and the US, present their plans to promote electric vehicles. In October 2022, the EU Parliament approved a reduction in CO2 emissions from new vehicles of 55% for passenger cars and 50% for light commercial vehicles such as vans and vans by 2030, compared to 2021. By 2035, this reduction must be 100% – meaning new passenger cars and vans must be emission-free. For trucks weighing more than 16 tons, the planned reduction is 30% from 2030; however, it is expected that even stricter regulations will follow.

As a contribution to nature conservation, as a competitive advantage, and for a positive ESG rating, many companies are taking steps to comply with sustainability reporting regulations and CO2 reduction.

For the automotive industry with its car and truck manufacturers and other stakeholders, the new EU targets primarily mean major changes – but also a great opportunity for innovation and radical, sustainable transformation of their own products, services and business processes. German passenger car manufacturers are meeting the challenge of sustainable mobility mainly by further developing the electric motor on the basis of battery and fuel cell technology: Mercedes Benz wants to stop launching vehicles with combustion engines on the market as early as 2030, Opel even as early as 2028.

The example of German IT service provider Bridging IT GmbH shows that the implementation of regulations and the use of sustainable mobility is already possible in the company’s own fleet. As early as 2011, the company began replacing individual combustion vehicles with e-vehicles. By 2015, the company had the largest e-fleet in Germany to date – and it continues to grow.

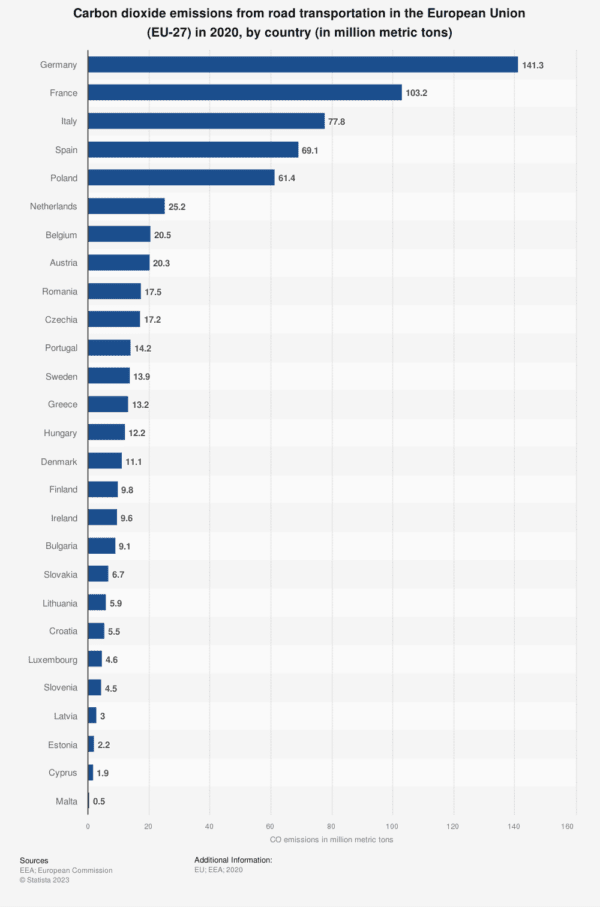

So far so good. But what about freight fleets? After all, the big hulks on two to four axles have enormous CO2 emissions – with 141.3 million tons of CO2 emissions in 2020, Germany is clearly the EU leader in road transport. And that is anything but sustainable.

Carbon dioxide emissions from road transportation in the European Union in 2020 (Source: https://www.statista.com/statistics/1236750/road-transportation-greenhouse-gas-emissions-eu/)

Truck Fleet to Zero – how a logistics company successfully implements sustainable mobility.

First published at the 44th International Vienna Motor Symposium from 26.4.-28.4.2023 in Vienna in detailed elaboration.

The company Mosolf Transport Solutions GmbH from Kirchheim/Teck shows that it can also be done differently, which is almost climate-neutral. The leading technology and logistics service provider for the automotive industry wants to convert part of its fleet to e-trucks in a comprehensive transformation project. Managing Director Egon Christ now presented the results of the first project phase in close cooperation with Magility GmbH at the 44th International Vienna Motor Symposium.

Impressions from the symposium

Sustainable mobility poses major challenges for logistics companies

The switch to new drive technologies poses countless major challenges: Not only must it be possible quickly and easily – compared to existing diesel technology, a new technology must above all be comparably robust, durable and reliable. Under no circumstances must there be risks in the operational area or disadvantages in competition or costs. In the case of e-mobility, there are additional factors such as the development of an operational and the use of public charging infrastructure, the question of government subsidy programs for the development of these structures and the renewal of the fleet. Operationally, profitability assessments, risk understanding and risk management in the TCO calculation come into play in the technical transformation during implementation. At the same time, the complexity of the change is also influenced by external factors, such as changing vehicle acquisition costs, energy costs that are currently difficult to calculate, and also highly volatile factors such as tolls, tax laws, GHG regulations, and subsidy guidelines.

How transformation can succeed

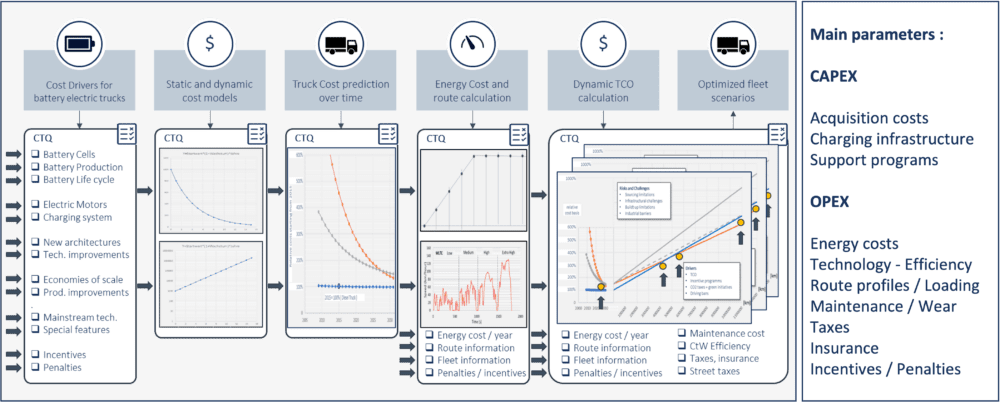

The design-to-quality model

Due to the complexity of the challenges, Mosolf relied on a structured transformation path that reliably maps, evaluates and tracks the economic and technical challenges. It used a design-to-quality model that evaluates different technologies and energy options and boils it down to the most important parameters.

Overall assessment model based on a “design to quality” design (Source: Mosolf/Magility GmbH, 2023)

In order to calculate the total cost of ownership, a total cost model was developed for the acquisition costs and the operating costs. Of particular relevance here are also: the expenses for the charging infrastructure, subsidy programs, deployment profiles, charging, maintenance and wear and tear, as well as taxes, insurance and toll costs.

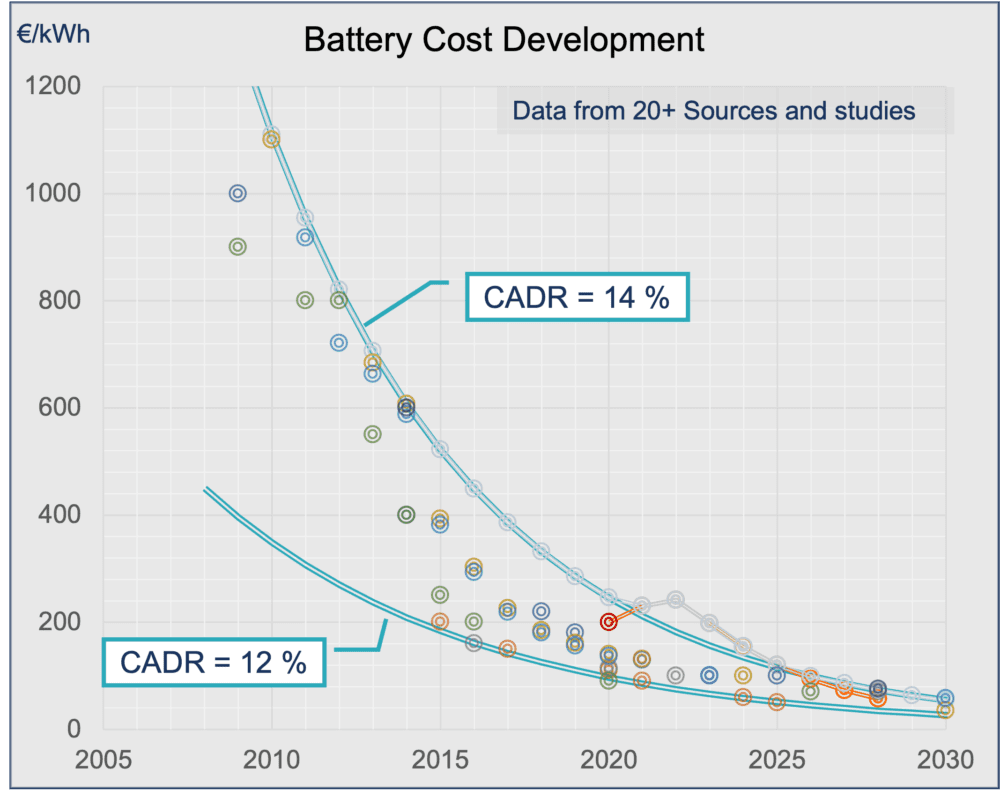

The results of the overall model revealed overlaps between the technology options over the operating life of the vehicles, which were then used to create a decision matrix. The most important parameter in the cost model for vehicle acquisition costs was the cost development curve for battery technologies – this has the greatest impact on cost reduction. Economies of scale also massively reduce the costs for electric drives and charging technologies.

Cost development curve for battery systems from 2009 to 2030 (Source: Mosolf/Magility GmbH, 2023)

It was clear to see that a clear direction of cost development for batteries has been emerging since 2009. This analysis was based on more than 20 sources and studies.

Further insights were gained, for example, from a dynamic cost calculation. This involved forecasting technologies (diesel, fuel cell and battery electric vehicles) and their potential for the future as well, using various CADRs and CAGRs:

- different ranges

- different technologies and architectures

- available public funding programs

- emission requirements

Insights into sustainable mobility for logistics companies

Overall, many valuable insights into a transformation process towards the use of battery-powered vehicles were gained in project phase 1:

- Dynamic cost considerations allow procurement scenarios to be planned professionally and holistically.

- Decision matrices help management to optimize the conversion of their fleets along typical usage periods.

- New battery technologies and vehicle architectures will enable further cost reductions.

- Significant reductions in charging times can already be achieved with MCS (megawatt charging system) charging technology. Charging technology for trucks weighing more than 16 tons will continue to develop dynamically.

- In view of the not inconsiderable challenges, it was essential to support the decision-making process with professional opportunity and risk management, which can provide information about the risks and opportunities of the project at an early stage.

Traditional decision-making processes rarely work well for this type of transformation – modern decision-making processes are more far-reaching and complex, as a wider range of technologies is available and opportunities, potentials and risks have to be assessed. When deciding for or against electric drives and sustainable mobility, companies must also weigh whether to build their own infrastructure or use external options. Government subsidies and the responsibility for entrepreneurial action naturally also play a major role.

The new decision-making process for the transformation to electromobility involves mapping future cost trends using digital twins that anticipate risks and fluctuations in energy costs. Investment costs are strongly influenced by use cases that determine when cost parity is achieved. The level of ambition for transformation can be slow, medium or fast.

Sustainable truck mobility is already a reality today

One thing is certain: business models are now being developed in the direction of sustainability and future viability. At Mosolf, the first step has been taken: The first electric trucks have been procured and the charging infrastructure has been set up. Test operations have begun and the next wave of procurement is being planned.

Would you also like to take the path to sustainable mobility? Our experts will be happy to support you in your transformation project!