Electrification plays a crucial role in sustainable wine production, facilitating the modernization of vineyard operations to enhance energy efficiency, reduce environmental impact, and actively support energy transition goals.

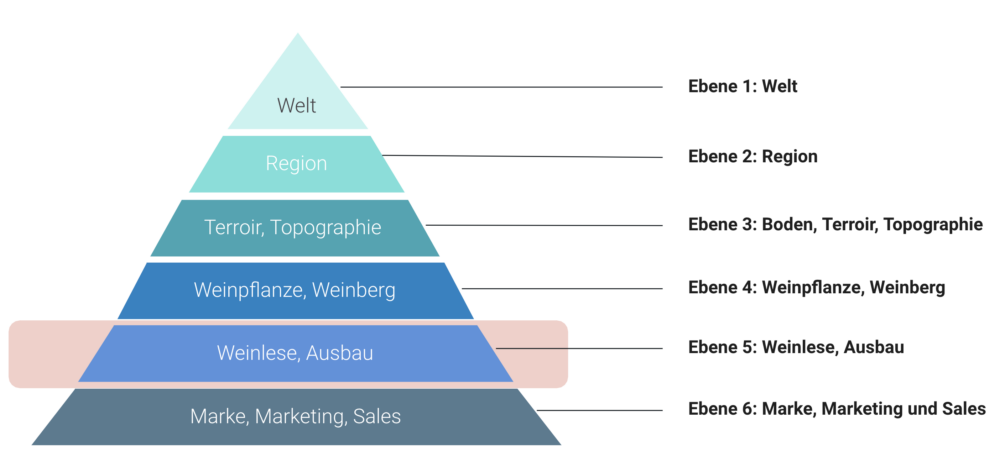

In Level 5, focusing on vineyards and grapevines, electrical technologies offer diverse opportunities for optimizing grape varieties, cultivation methods, and maintenance practices to reduce environmental footprint:

Electric technologies contribute to improving energy efficiency by making traditional processes more efficient and resource-friendly. Reducing environmental impact is achieved through the use of eco-friendly electrical devices throughout the wine production cycle.

Areas of application for electrical technologies in viticulture include

Irrigation for sustainable wine production

- Electric pumps enhance irrigation by ensuring efficient and resource-friendly water supply.

- The electrical technology optimizes water usage and contributes to sustainable irrigation practices.

Soil cultivation for sustainable wine production

Electric devices preserve the soil during cultivation by offering specific advantages compared to conventional, fossil-fueled machinery:

- Reduced soil compaction: Electric devices are often lighter than their conventional counterparts. Their lower weight leads to reduced soil compaction, meaning the soil is less densely packed. Reduced compaction promotes better water permeability and facilitates plant root growth.

- Precise control: Electric devices enable more precise control and adjustment during soil cultivation. This precision allows winemakers to better regulate the depth and intensity of soil cultivation, thereby minimizing soil disturbance.

- Pollution prevention: Electric devices do not emit exhaust gases on-site. This reduces air pollution in the work environment and minimizes the deposition of harmful substances in the soil, contributing to healthier soil quality.

The use of electric tools minimizes soil compaction and erosion, thereby improving soil quality in the long term and contributing to sustainable agriculture and wine production.

Pruning for sustainable wine production

Electric devices enable efficient and precise pruning of grapevines, optimizing maintenance processes by:

- Precision and control: Electric devices often offer advanced technologies for precise pruning and control. This allows winemakers to tailor the pruning exactly to the needs of the vines to ensure optimal growth conditions.

- Preservation of vines: Precise pruning prevents healthy parts of the vines from being accidentally removed. This helps maintain the health of the vines and maximizes grape yield and quality.

- Increase in efficiency: Electric devices are often more powerful than conventional ones, allowing for faster processing of large vineyard areas. This increase in efficiency leads to time and resource savings in vineyard maintenance.

- Comfort of work: Electric devices are generally lighter and easier to handle than manual tools or heavier conventional machinery. This makes the work of winemakers easier and contributes to a more pleasant working environment.

This precision contributes to the health of the vines and promotes sustainable wine production.

Fertilization for sustainable wine production

Electric devices support efficient and precise fertilization, enabling more effective resource utilization.

- Electric fertilizer spreaders and dispensers are often equipped with advanced dosing technology. This allows for precise control over the quantity and distribution of fertilizers. Winemakers can dose the exact amount of nutrients required by the plants without excess.

- Variable fertilizer application: Electric devices can be equipped with variable rate systems based on data such as soil analysis and plant requirements. This enables customized fertilization, adjusting the quantity of nutrients supplied to different areas of the vineyard or even individual vines.

- Real-time monitoring and adjustment: Electric fertilizer spreaders can often be monitored and adjusted in real-time. This allows winemaker to respond to changing conditions during the fertilization process to ensure optimal nutrient supply.

- Minimization of environmental impact: Precise dosing and application of fertilizers help avoid over-fertilization. This reduces the risk of nutrient loss, minimizes water pollution from excess fertilizers, and contributes to reducing environmental impact.

Resource-efficient wine production – The Harvest

Electric harvesting machines contribute to efficient and resource-efficient harvesting by offering various advantages:

- Precise control and selection: Electric harvesting machines enable precise control during the harvesting process. This ensures that only ripe grapes are harvested, while unripe or damaged fruits are sorted out. As a result, the quality of the harvested grapes is improved.

- Efficient working speed: Electric harvesting machines are often able to work at a constant and efficient speed. This leads to faster harvesting and allows for efficient utilization of labor and resources.

- Reduced physical strain: Compared to manual harvesting methods, electric harvesting machines reduce the physical strain on workers. This contributes to improved working conditions and the health of the harvesters.

- Energy efficiency: Electric harvesting machines can be more energy-efficient than their conventional, fossil-fueled counterparts. This helps reduce overall energy consumption and minimize the ecological footprint of the harvesting machines.

- Minimization of losses: Through precise grape capture and handling, electric harvesting machines minimize the loss of harvested produce. This helps maximize overall yield and conserve valuable resources.

Overall, these factors contribute to increased overall efficiency and resource-efficient harvesting in viticulture through the use of electric harvesting machines.

Example: Digitization in Harvesting and Winemaking – BlueCircle Cloud Platform

At level 5, encompassing harvesting and winemaking, the BlueCircle Cloud Platform stands out as a pioneering example of utilizing digitalization technologies in viticulture. This innovative platform combines advanced Artificial Intelligence (AI) with optimization functions to enhance control over the entire wine and grape supply chain, while attracting and educating top-notch viticulture talents.

Key Features of the BlueCircle Cloud Platform

AI-based software for comprehensive control:

- The platform offers a software solution that enables precise control over all processes of the wine and grape supply chain.

- By implementing advanced AI, data-driven decisions are promoted, and optimization opportunities are identified.

Optimization of S&OP (Sales and Operations Planning):

- The software supports Sales and Operations Planning (S&OP) through accurate forecasts year-round.

- Improved S&OP allows for efficient planning and alignment of operational processes with sales objectives.

AI-driven real-time alerts:

- Utilization of AI for real-time alerts on unpredictable weather and other conditions affecting yield, quality, ripening, and harvest.

- Data-driven harvest scheduling to prepare for changing environmental conditions, ensuring harvest security.

- A continuous learning process enables all users to benefit from the latest developments and best practices.

The BlueCircle Cloud Platform stands out as an example of innovative digitalization in viticulture by not only increasing efficiency but also improving the quality of wine production through data-driven decisions and continuous optimization. By integrating state-of-the-art technologies into harvesting and winemaking, a forward-thinking, sustainable approach to viticulture is facilitated.

Electrification in viticulture is thus more than just a technological advancement. It enables sustainable practices for resource-efficient wine production, reduces the ecological footprint, and actively contributes to the energy transition. Winemakers who integrate these technologies into their operations not only benefit from efficiency gains but also contribute to making viticulture more sustainable and future-proof. Contact our experts for professional exchange. We are happy to advise you.